Strategy on tap!

As the craft beer industry matures, brewing entrepreneurs are challenged to operate efficiently and produce a reliable, quality product.

In this Data-Driven Insights series, I’ll walk you through an analytic assessment of beer production. Over 8 episodes, I’ll detail strategies that most craft breweries can use to reduce ingredient costs by 10-20%, decrease their carbon footprint, and hit timeline and quality goals for production.

Table of Contents

EPISODE 1: MILLING

Dialing in the mill is always the introductory goal of my brewery assessment. Given that the mill is the most upstream element in the production chain, it is crucial to be confident in its performance before troubleshooting the mash and lauter. Additionally, it is common to see a quick 5% savings on malt due to the snowballing positive effects of a properly set mill.

Ideal mill settings vary due to mash process, lautering technology, malt choice, and a brewery’s prioritization of efficiency or wort quality (tannins). The proper settings become increasingly unique as a mill wears down. Traditionally, mill settings are determined by sieve testing. However, data analysis is a brewery-tailored and easily monitored approach to either complement or replace sieve tests.

To determine the cause of a hot-side extract issue, it is essential to have accurate first runnings gravity measurements. My suggestion is to take the measurement immediately after you begin the sparge. It is also important to have consistent SOPs for the vorlauf and for sparge start timing, as these can change the homogeneity of the mash gravity.

As you can see from this model of a combo mash/lauter tun below, the runnings will first be diluted by the foundation water and finally by the sparge water. Sampling the wort immediately after sparge start generally lands you in the 10-20 minute plateau at peak runnings gravity. Measurements here are stable enough to replicate from day to day.

Model 1: Taking a reliable first runnings measurement

The red stars mark the start and end of the ideal first runnings measurement period.

The analyst must now create a group of usefully comparable brews. A core lager brand is often best, as they may have simple grists, long mashes, and high-performance malts. Given few external variables, the trends are a clear reflection of milling performance.

Model 2: Identifying an ideal mill gap

First runnings gravities will peak or plateau when 100% of kernels are cracked and available to extract. For this brewery’s single-roller mill, the ideal gap appears to be at .055 inches.

The perfect grind for your brewery depends upon the flow dynamics of the lauter tun. With good performance, a lauter tun can handle a finer grid that extracts more starch. To measure the impact of your grind upon both extract (fine grind) and lautering (coarse grind), it can be useful to graph both starch conversion % and total mash efficiency % against your sieve test results.

Model 2B: Identifying an ideal sieve test result

At this brewery, there appears to be a significant loss of extract until their #14 sieve captures 35-40% of the milled grist.

Let’s explore the starch conversion % metric. Conversion % approximates the % of starch that is successfully converted to sugar during the mash. While that is of interest in its own right, conversion % also improves the pace and breadth of hot-side research by making first runnings measurements comparable between all brews.

The goal for starch conversion % is to remove mash thickness as a variable. The grist’s potential extract and mash water volume are used to determine the maximum possible first runnings gravity. The actual first runnings gravity, as a % of its ideal, is the starch conversion %

For example, a grist with 1000 lbs of 75% FGAI malt and 300 gallons of water would have a maximum first runnings gravity of 23.0 ºP. If your measurement is 21.5 ºP, then the starch conversion % in that brew would be:

Starch Conversion % = 21.5 ºP / 23.0 ºP = 93.5%.

Let’s dive into some charts to see how to interpret this kind of data.

Model 3: Graphing starch conversion against mash efficiency: strong correlation

When conversion is highly correlated to mash efficiency, it indicates that milling or mash issues are the culprit.

In this case, an 88% correlation indicates that 88% of their mash variability is due to mill and mash issues, rather than lautering.

Model 3b: Graphing starch conversion against mash efficiency: weak correlation

A low correlation of starch conversion to mash efficiency indicates that the lauter is responsible for variability in performance.

Here, only 11% of the variability is due to the mill or mash.

Model 4: Monitoring the mill with first runnings

A milling issue developed in late October and has reduced starch conversion % by ~5% since.

The mill should be recalibrated and rollers realigned.

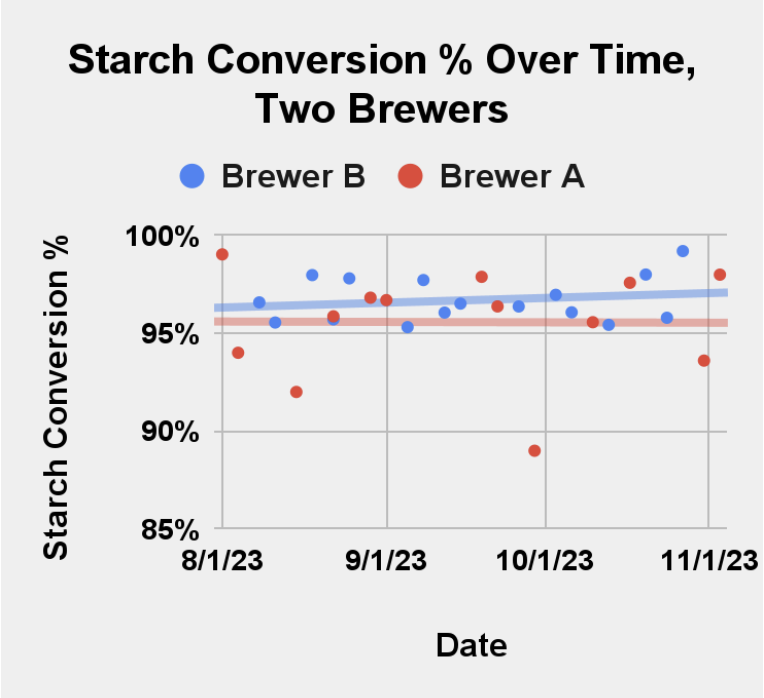

Model 5: Differences between brewers indicate issues with mash SOPs

Mash issues produce inconsistent data that often vary by brewer. Milling issues, in contrast, produce consistent underperformance.

This chart shows that Brewer A has variable performance that indicates a likely issue with mash technique.

Model 6: Trends for individual malts

Here, grists with a higher wheat malt % have a lower starch conversion %.

This is likely due to wheat’s smaller kernel size, and indicates a 13.7% extract upside from the grist’s wheat if the brewery adjusts their mill before brewing these wheat-centric brands.

With the mill delivering strong, well-monitored performance, you’re ready to evaluate your mash protocols. In the next episode, I’ll cover analytic strategies that help brewers hit mash temperatures, control fermentability, blend properly during mash-in, and typically save another 3% on malt costs.

EPISODE 2: MASHING

The mash is one of the most complex process points in brewing, with protocols driving the qualities of sweetness, clarity, foam, body, wort tannins, and more. If we wish to produce a consistent product, we must control mash duration, temperature, pH, diastatic power, water-to-grain ratio, and mash homogeneity. In this episode we’ll explore the essential role of data analysis in this task.

Our first target is the grain-in. It is useful to establish methods that enable every brewer to grain in at a similar rate, and to then have data-driven guidelines for the corresponding gallons/minute of water. Even distribution of strike water reduces dough balls, creates more homogenous mash temperatures, and allows for thicker mashes, which are typically more efficient to lauter.

We use timestamps at the beginning and end of grain-in to determine a grain-in duration, then divide our total grist lbs by that duration to get a lbs/minute rate of grain-in.

Grain-In Lbs/Minute = Total Grist Lbs / Grain In Duration

Model 1: Standardizing grain-in

Grist lbs and grain-in duration are used to calculate the lbs/minute rate of grain-in. This brewery improved their SOP for grain-in around September 1, resulting in a more consistent 77 lbs/minute pace.

Having a known and controlled grain-in rate can support the determination of water usage rates. The calculation for strike gallons/minute is as follows:

Strike Gallons / Minute = (Total Water - Foundation Water) / (Lbs/Min / Total Grist Lbs)

It is wise to set aside 2-5% of your total water so that brewers do not run out of water before grain-in ends. When extra water must be added to wet the last of the grain, it can compromise your mash temperature, mash thickness, and the comparability of the batch in lautering analysis.

With stable protocols for tun preheating, grain-in, and perhaps some recirculation during grain-in, you should be positioned with a homogenous mash for which temperature can accurately be measured.

Model 2: Mash Temperatures

Mash temperatures fluctuate seasonally and are impacted by detailed variations of brewer technique.

Model 2b: Calculating Strike Temps

With records of the strike and mash temperatures in each batch of a brand, you can determine how much higher strike temp should be seasonally.

For this brand, strike temperature should be ~9 F higher than the intended mash temp in winter, but only ~5 F higher in summer. Strike - mash temp may also be usefully graphed against daily brewery temperature, if available.

Model 2c: Evaluating step-mash temperature precision

This brewery accurately hits temperatures for its strike infusion and heated step 4, but its two decocted steps are often 1-8 degrees high.

The brewery should aim to reduce the step 2 & 3 temperature by ~4F, while also exploring causes of these highly variable results.

Model 3: Mash pH

Changes to water and grain supply, as well as mash technique, can send mash pHs off track.

I suggest using first runnings pH as your mash pH reading, given the existing attention to the quality of that sample.

The analyst may have an acid addition model which can be adjusted to match your results.

Model 4: Mash Duration

My preferred method of controlling mash duration is to sum grain-in, mash, and vorlauf durations by using timestamps for grain-in start and lauter start. Enzymes are active throughout these processes.

Here we can see that Brewer B has recently been giving batches 20 more minutes than is called for. This may be a result of multitasking, issues with brewhouse flow during second turns, or brewer attention to detail.

Model 5: Efficiency differences between brewers indicate issues with SOP execution

Mash SOP issues produce inconsistent data that often vary by brewer. Milling issues, in contrast, produce consistent underperformance.

This chart shows that Brewer A has variable performance that indicates a likely issue with mash technique.

With high visibility over grain-in, temperature, pH, and brewer technique, you’re well set for R&D efforts and research into the nature of your mashes.

Model 6: Defining brand goals with sensory

This brewery’s flagship IPA gets the best sensory feedback when attenuation hits ~79%.

Let’s evaluate common variables affecting fermentability. These analytics can make use of existing variability in production data, but ideally the data is prepared through a strategic, gradual change of a single mash protocol.

Model 7: Impact of mash temperature upon fermentability

The degree to which mash temperature impacts fermentability is affected by diastatic power, mash thickness, and mash duration.

For this brand, at this brewery, attenuation increases by 1.24% for every degree fahrenheit in the mash.

Model 8: Impact of mash thickness on fermentability

The impact of mash thickness on fermentability can be significant, but is multivariable. Typically, thinner mashing leads to lower fermentability at “normal” temperatures, but can lead to higher fermentability at high temperatures.

The presence of charting to this detail brings greater attention to detail during production. Brewers are aware that their precision has real impact.

Model 9: Diastatic Power and Fermentability

Diastatic power is a key consideration when defining the required mash duration and anticipated fermentability.

Model 10: Haze and mash duration

As this brewery explored the use of shorter mash durations, they noticed a significant increase in haze in their flagship lager.

Haze measurements during centrifuge transfer often provide easy-to-collect data for your clarity research.

In the next episode, we’ll explore lautering analytics, including the impact of mash enzymes, rice hulls, mash thickness, tech maintenance, and more upon your lautering efficiency. I’ll show you how a brewery can create a mash efficiency prediction formula using its own data, then construct a “mash performance” metric that makes efficiency comparable for all brands.